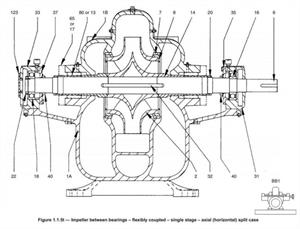

B-SP Bottom Suction Splitcase

The B-SP splitcase pumps are used in a variety of commercial, industrial

& municipal applications but where limitations are placed on the location

of the suction piping. This version of the SP splitcase product line features

a bottom suction connection allowing the pump to connect to existing system

piping located directly below the pump that cannot be moved. This heavy

wall, Francis design, enclosed, bronze impeller provides a very broad

operating range. The casing features an exclusive

Thru-Bore line boring machining operation that greatly simplifies manufacturing

and maintenance. Bearing & bearing housings can be inspected and/or

replaced without removing the top part of the casing. The rotor assembly

also features completely removable and replaceable packing housings/seal

chambers with a replaceable vortex suppressor. The centerline of the pump

has also been increased to ensure that discharge flange does not interfere

with the pump foundation. Each model features 250# cast dimensional flanges

and 420 stainless steel shafting. These industry exclusive features makes

this product adaptable for the building trades, HVAC, cooling tower, steel

mill, mining, power generation, municipal and oil & gas applications.

The B-SP splitcase pumps are used in a variety of commercial, industrial

& municipal applications but where limitations are placed on the location

of the suction piping. This version of the SP splitcase product line features

a bottom suction connection allowing the pump to connect to existing system

piping located directly below the pump that cannot be moved. This heavy

wall, Francis design, enclosed, bronze impeller provides a very broad

operating range. The casing features an exclusive

Thru-Bore line boring machining operation that greatly simplifies manufacturing

and maintenance. Bearing & bearing housings can be inspected and/or

replaced without removing the top part of the casing. The rotor assembly

also features completely removable and replaceable packing housings/seal

chambers with a replaceable vortex suppressor. The centerline of the pump

has also been increased to ensure that discharge flange does not interfere

with the pump foundation. Each model features 250# cast dimensional flanges

and 420 stainless steel shafting. These industry exclusive features makes

this product adaptable for the building trades, HVAC, cooling tower, steel

mill, mining, power generation, municipal and oil & gas applications.

Flow & Pressure Characteristics

Flows To: 30,000+ GPM (6,813 m³/hr)

Heads To: 550 Feet (168 m)

Temperatures To: 300ºF (149ºC)

Speed Ranges: 500 RPM To 3600 RPM

Size Range

2×3-10 (50/26) – 32×40-40 (800/100)

Features & Benefits

- Cast iron casing/bronze impeller

- Exclusive Thru-Bore casing that allows packing housings/seal chambers to be removed with the rotor assembly

- Bearing housing can be inspected and/or replaced without removing casing top

- Bearings can be inspected and/or replaced without removing casing top

- Grease lubricated bearings with optional oil lubrication

- Oil lip sealed bearings with optional bearing isolators

- Fully removable rotor assembly

- Packing housings/seal chambers are removable with rotor assembly

- Packing standard with optional CPS-Pumps exclusive Carbon/Silicone-Carbide/Viton mechanical seal or optional single or double cartridge mechanical seal

- Multi-vane, enclosed, high efficiency impeller with broad band efficiency

- Bronze, API style, stepped case wear rings

- 125# suction/125# discharge flange with 250# cast dimensions standard

- Suction & discharge gauge connections standard

- Turned, ground and polished 420 stainless steel shaft standard

- Heavy duty, 304 stainless steel shaft sleeves with exclusive external o-ring groove

- Packing standard with optional component and/or cartridge mechanical seals available

- Single row inboard and single row outboard bearings with optional double row at either location

- 50,000+ hour minimum L10 bearing life standard

Available Metallurgies

- Cast iron, ductile iron, all bronze, all 304 stainless steel, all 316 stainless steel

Markets

- Building Trades

- Chemical Processing

- Food & Beverage

- General Industry

- Irrigation & Agriculture

- Marine & Offshore

- Mining & Aggregate

- Power Generation

- Oil & Gas

- Pharmaceutical

- Pulp & Paper

- Water Resources