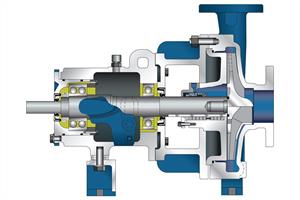

CSD Process ANSI

The CSD Process ANSI pumps are used in a variety of industrial applications.

CSD ANSI Process pumps are industry leading from a feature & benefits

standpoint. This heavy wall, reverse-vane, 304 investment cast stainless

steel impeller design provides a durable and dependable product and is

perfectly suited for petrochemical applications. These heavy duty process

pumps feature double row outboard and single row inboard bearings standard.

Each bearing housing is oil-lubricated to ensure maximum bearing life.

Grease lubrication and oil mist bearing lubrication is also optional. The

Nex-Gen power frame assembly is industry leading in that it is very easy to adjust

impeller running clearances by using an integrated micrometer adjustment.

This allows for ease in impeller clearance readjustment and dramatically

reduces start-up time in the field. This fluid end is designed to be used

in the most aggressive of applications. The flexibility of material combinations

makes this product adaptable for the steel mill, mining, power generation

and oil & gas applications.

The CSD Process ANSI pumps are used in a variety of industrial applications.

CSD ANSI Process pumps are industry leading from a feature & benefits

standpoint. This heavy wall, reverse-vane, 304 investment cast stainless

steel impeller design provides a durable and dependable product and is

perfectly suited for petrochemical applications. These heavy duty process

pumps feature double row outboard and single row inboard bearings standard.

Each bearing housing is oil-lubricated to ensure maximum bearing life.

Grease lubrication and oil mist bearing lubrication is also optional. The

Nex-Gen power frame assembly is industry leading in that it is very easy to adjust

impeller running clearances by using an integrated micrometer adjustment.

This allows for ease in impeller clearance readjustment and dramatically

reduces start-up time in the field. This fluid end is designed to be used

in the most aggressive of applications. The flexibility of material combinations

makes this product adaptable for the steel mill, mining, power generation

and oil & gas applications.

Flow & Pressure Characteristics

Flows To: 7,400 GPM (1,680 m³/hr)

Heads To: 985 Feet (300 m)

Temperatures To: 500ºF (260ºC)

Speed Ranges: 900 RPM To 3600 RPM

Size Range

1×1.5-6 (26/16) – 8×10-16 (200/40)

Features & Benefits

- Ductile iron casing/investment cast 304 stainless steel impeller

- Reverse-vane impeller with hydraulic balancing holes

-

Choice of 5 engineered rear covers to meet job site requirements

- FMS

- FML

- FMI

- CBS

- CBL

- Oil lubricated power frame

- Standard bearing isolators

- Next-Gen power frame with full micrometer power frame adjustment that has 0.002″ graduations cast on the bearing carrier

- Multi-vane, semi-open, high efficiency impeller with broad band operating range

- 125# suction/125# discharge flange drilled & tapped for easy connection to system piping

- Drilled & tapped suction & discharge flanges for easy connection to system piping

- Suction & discharge gauge connections standard

- Turned, ground and polished 420 stainless steel shaft standard

- Heavy duty, 304 stainless steel shaft sleeve

- Packing standard with optional component and/or cartridge mechanical seals available

- Single row inboard and double row outboard bearings with optional duplex angular contact at outboard location

- 50,000+ hour minimum L10 bearing life standard

Available Metallurgies

- Cast iron, ductile iron, all bronze, all 304 stainless steel, all 316 stainless steel, all Cd4MCu, all Alloy 20, All Hastalloy (B&C), all 2205 super duplex stainless steel, all 2507 super duplex stainless steel, Cr28, all Titanium

Markets

- Chemical Processing

- Food & Beverage

- General Industry

- Marine & Offshore

- Mining & Aggregate

- Power Generation

- Oil & Gas

- Pharmaceutical

- Pulp & Paper

- Water Resources