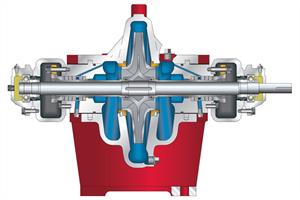

FP-SP Splitcase Pump

The FP-SP splitcase product line is one of the most common pumps used in

the fire production markets today. This product can be electric or diesel

engine driven and is available in many flows and pressures in both 50

& 60 cycle speeds. CPS-Pumps offers single and multistage splitcase

pumps covering a very broad flow and pressure range. Packing and grease

lubrication round out the list of standard features that appear in our

fire pump product line. The performance is based off of our proven SP

& HMM product lines.

The FP-SP splitcase product line is one of the most common pumps used in

the fire production markets today. This product can be electric or diesel

engine driven and is available in many flows and pressures in both 50

& 60 cycle speeds. CPS-Pumps offers single and multistage splitcase

pumps covering a very broad flow and pressure range. Packing and grease

lubrication round out the list of standard features that appear in our

fire pump product line. The performance is based off of our proven SP

& HMM product lines.

Flow & Pressure Characteristics

Flows To: 250 GPM To 4000 GPM (57 m³/hr To 908 m³/hr)

Heads To: 482 PSI (168 m)

Speed Ranges: 1500 RPM To 3600 RPM

Size Range

2.5×3-10 (65/24) – 10×14-20 (250/50)

Features & Benefits

- Cast iron casing/bronze impeller

- Exclusive Thru-Bore casing that allows packing housings to be removed with the rotor assembly

- Bearing housing can be inspected and/or replaced without removing casing top

- Bearings can be inspected and/or replaced without removing casing top

- Grease lubricated bearings standard

- Oil lip sealed bearings with optional bearing isolators

- Fully removable rotor assembly

- Packing housings removable with rotor assembly

- Packing standard

- Multi-vane, enclosed, high efficiency impeller with broad band operating range

- Bronze, API style, stepped case wear rings

- 125# suction/125# discharge flange with 250# cast dimensions standard

- Drilled & tapped suction & discharge flanges for easy connection to system piping

- Suction & discharge gauge connections standard

- Turned, ground and polished 420 stainless steel shaft standard

- Heavy duty, 304 stainless steel shaft sleeves with exclusive external o-ring groove

- Single row inboard and single row outboard bearings with optional double row at either location

- 50,000+ hour minimum L10 bearing life standard

- Electric or Diesel engine driven

Available Metallurgies

- Cast iron, ductile iron, all bronze, all 304 stainless steel, all 316 stainless steel

Markets

- Fire Protection